According to a recent report by the MIT Technology Review website, the research team at Princeton University in the United States has developed the world's first silicon photonic neuromorphic chip and has proved that it can increase the computing speed by nearly 2000 times.

The research team etched each node of the new chip in the form of a mini circular waveguide into a silicon base, allowing light to circulate through it. When light is input to the node, the output of the laser operating at the node threshold is modulated, and the output of the laser is fed back to the node, creating a feedback circuit with non-linear features. With regard to the extent to which this nonlinear behavior mimics neural behavior, researchers have demonstrated that its output is mathematically equivalent to a "continuous-time recurrent neural network." Researchers used a network of 49 photon nodes to simulate the neural network and used it to solve the mathematical problems of differential equations. They found that this silicon photon neuromorphic chip can compare the arithmetic Speed ​​up 1960 times.

This result makes the neuromorphic chip speed has been significantly improved, help to promote facial recognition, object recognition, natural language processing, machine translation and other artificial intelligence technology development.

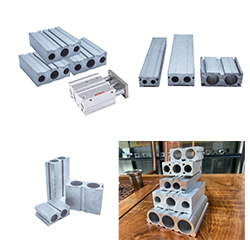

TCN/TN Pneumatic Cylinder Barrel

Guided pneumatic cylinder adds another guided rod on the basis of the single rod or double rod cylinders to make the movement trajectory of the cylinder more accurate, which can effectively increase the performance of resisting side load and reduce the influence of lateral swing. Most regular guided air cylinder is MGP series.Pneumatic Cylinder Tube.

Both dual rod air cylinder and guided air cylinder have a magnetic ring inside, which is convenient for the magnetic switch to detect the position of the piston movement. There are mounting holes on three sides of the fixed plate of double rod air cylinder and guided pneumatic cylinder, which are convenient for multi-directional installation and use.Air Cylinder Barrel.

Parameter:

â—† Working pressure: 0.15~0.7MPa

◆ Ambient temperature: -20~70℃

â—† Applicable fluid medium: Compressed air, non-corrosive gas

â—† Operating speed: 50-500mm/s

A three-axis cylinder typically refers to the use of three independent linear cylinders in a system to achieve motion in three-dimensional space. In automation and robotics technology, such configurations can be used to achieve precise position control and object movement. Each cylinder is typically responsible for one axial movement (e.g. X, Y, Z).

Here are some key points about three-axis cylinders:

Structure:

Usually composed of three independent linear cylinders.

Each cylinder is installed in a mutually perpendicular direction, forming a three-dimensional coordinate system.

Application:

Part positioning on automated assembly lines.

Position adjustment of end effectors in industrial robots.

Accurate movement in material handling systems.

Sample processing in laboratory equipment.

working principle:

By compressing air, the piston is pushed to move inside the cylinder.

The extension and contraction of the piston rod drives the mechanical structure to move along a specified axis.

The combined motion of three axes can achieve complex spatial trajectories.

Control system:

PLC (Programmable Logic Controller) or specialized motion controller may be required to coordinate the actions of the three cylinders.

Sensors are used to provide feedback on position information to ensure precise control.

characteristic:

Compact structure, suitable for application environments with limited space.

Quick action, suitable for high-speed operation scenarios.

Maintenance is relatively simple because the main components are pneumatic.

Dual axis cylinder usually refers to a specially designed pneumatic actuator that can generate motion in two directions. This type of cylinder is typically used in applications that require linear motion on two axes simultaneously or separately. Here is some basic information about dual axis cylinders:

Basic concepts

Definition: A dual axis cylinder is a pneumatic component capable of producing linear motion on two axes simultaneously or separately.

Application: Widely used in automated production lines, material handling, precision positioning, and other situations that require multi axis control.

Structure and Type

Parallel dual axis cylinder: Two cylinders are arranged in parallel, and the piston rod can move synchronously or independently.

Coaxial dual axis cylinder: Two cylinders share a piston rod and control the movement of the two shafts through different air paths.

Other types: There are also specially designed dual axis cylinders, such as dual piston rod cylinders, which can install two piston rods on one cylinder block.

working principle

Compressed air drive: By using compressed air to push the piston inside the cylinder, it drives the piston rod or connecting piece to move along a predetermined axis.

Independent or synchronous control: Depending on the needs, the motion of each axis can be independently controlled, or two axes can be synchronized through specific design.

Control system

Electromagnetic valve: used to control the direction of airflow, thereby controlling the expansion and contraction of the cylinder.

Sensors: Displacement sensors or proximity switches can be installed to monitor the position of the piston and achieve precise control.

PLC or controller: It is usually necessary to coordinate the working sequence and speed of the cylinders through PLC or other controllers.

Application examples

Automated assembly: Dual axis cylinders can be used for positioning, clamping, or assembling parts.

Robot arm: As a part of the end effector of the robot, it achieves grasping and placing tasks.

Testing equipment: used in laboratories or quality control environments to simulate pressure or thrust testing.

characteristic

Compact: Compared to using two cylinders separately, dual axis cylinders have an advantage in space occupation.

Flexibility: Different travel lengths and installation methods can be customized according to application requirements.

Economy: Reduce installation space and costs while maintaining high performance.

TCN Pneumatic Cylinder Barrel,TN Pneumatic Cylinder Barrel,Dual Rod Air Cylinder Aluminum Tube,Dual Rod Air Cylinder Tube

Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com